Understanding H2S Training: Enhancing Safety in the Workplace

Hydrogen Sulfide (H2S) is a highly volatile and toxic gas that poses significant risks in various industries, particularly those involving oil and gas extraction, sewage treatment, and other workplaces where H2S is prevalent. Hence, H2S training is a crucial component of workplace safety protocols. This article explores the fundamentals of H2S training, its importance, the training process, and its impact on educational services and special education sectors.

What is H2S?

H2S, commonly known as hydrogen sulfide, is a colorless gas with a distinct smell of rotten eggs at low concentrations, which can quickly become unbearable. It is heavier than air and can accumulate in low-lying areas, making it hazardous. The gas is produced naturally in various environments, including polluted water, sewage systems, and in industrial processes such as petroleum refining. The toxicity of H2S is a major concern, as even small concentrations can lead to serious health issues or fatalities if not managed properly.

Importance of H2S Training

Implementing H2S training is vital for several reasons:

- Health and Safety: Protecting employees from the dangers of H2S exposure is of utmost importance. Adequate training helps workers recognize the risks and learn appropriate safety measures.

- Compliance with Regulations: Many industries are subject to regulatory standards that mandate H2S training (e.g., OSHA standards in the United States). Compliance is essential to avoid legal penalties.

- Crisis Management and Emergency Preparedness: Employees trained in H2S safety are better equipped to respond to emergencies, minimizing injury and damage to equipment.

- Workplace Culture: Promoting a safety-first culture enhances employee morale and productivity, fostering an environment where safety is prioritized.

Components of H2S Training

A comprehensive H2S training program typically includes the following components:

1. Understanding the Properties of H2S

Participants learn about the physical and chemical properties of hydrogen sulfide, including:

- Its toxicity and how it affects the human body

- Detection methods and the importance of continuous monitoring

- Emergency response protocols in case of exposure

2. Risk Assessment

Identifying high-risk areas and understanding situations where H2S exposure might occur is crucial. Training sessions often cover:

- Site-specific risk assessment strategies

- Recognizing unsafe conditions

- Implementing safety measures to mitigate risks

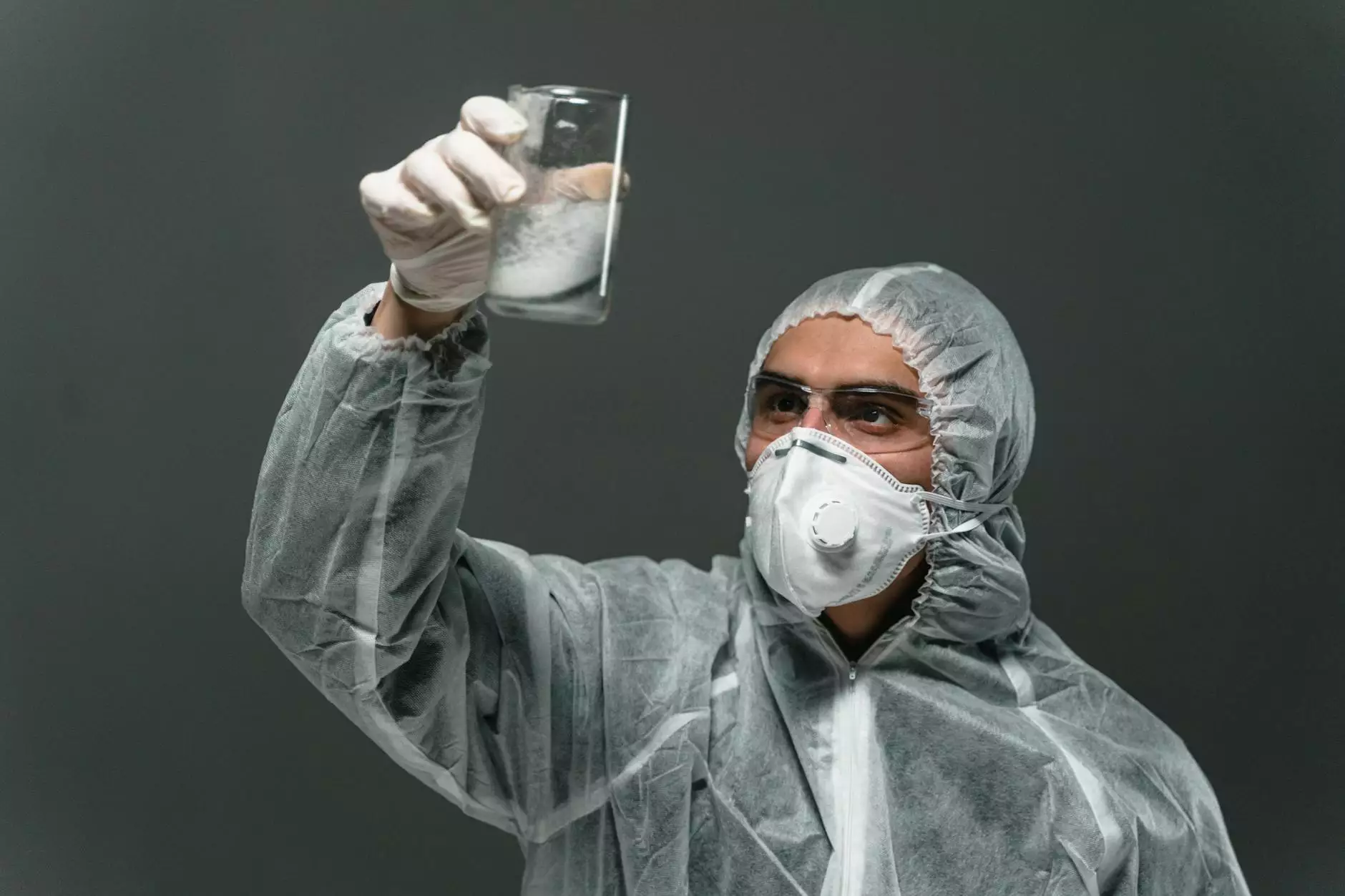

3. Use of Personal Protective Equipment (PPE)

A significant aspect of H2S training involves proper use and maintenance of PPE. Participants learn about:

- Types of PPE effective against H2S exposure (e.g., respirators, protective clothing)

- How to correctly wear and care for PPE

- When it is necessary to use PPE

4. Emergency Response Training

In case of an H2S leak or exposure, effective emergency response can save lives. Training includes:

- Emergency evacuation techniques

- First aid procedures for H2S exposure

- Use of safety equipment in emergencies, such as self-contained breathing apparatus (SCBA)

Methods of H2S Training Delivery

H2S training can be delivered through various methods, including:

- In-Person Training: Traditional classroom approach with hands-on demonstrations.

- Online Training: Flexible e-learning platforms that allow employees to complete training at their own pace.

- Simulation Training: Practical drills and scenarios that replicate real-life situations for better preparedness.

Benefits of Online H2S Training

As online education becomes more prevalent, H2S training is increasingly available through digital platforms. The benefits include:

- Accessibility: Employees can access training materials anytime and anywhere, making it easier to fit into busy schedules.

- Cost Efficiency: Reduces costs associated with travel and physical training environments.

- Interactive Learning: Online platforms often provide engaging materials through videos, quizzes, and interactive simulations.

Workplace Implementation of H2S Training

Integrating H2S training into the workplace involves several steps:

1. Assessing Training Needs

Evaluate the specific needs of your workforce and work environment. Different industries may expose employees to varying levels of risk.

2. Developing a Training Program

Create a structured training program that aligns with regulatory standards and is suitable for your workforce’s experience and knowledge level.

3. Providing Regular Training Updates

H2S training is not a one-time task. Regular updates and refresher courses are essential to ensure that employees remain informed about new safety practices and technologies.

Special Education and H2S Training

The concept of H2S training can also extend into the realm of special education. Safety education is vital for all students, including those with special needs. Training tailored for this demographic might include:

- Specialized instructional methods to accommodate learning differences.

- Visual aids and simplified materials that enhance understanding.

- Hands-on learning experiences that allow practical application in a controlled environment.

Conclusion

In summary, H2S training is a critical component of workplace safety, particularly in high-risk industries. By understanding the properties of hydrogen sulfide, conducting thorough risk assessments, and providing comprehensive training, organizations can protect their employees and ensure compliance with safety regulations. Moreover, the integration of H2S training within special education demonstrates the commitment to fostering safety awareness in all learning environments.

Investing in H2S training not only enhances safety measures but also cultivates a culture of safety, empowering employees to take responsibility for their own well-being and that of their coworkers. Whether through in-person courses or online platforms like h2sonlinetraining.com, it is imperative that organizations prioritize H2S training as part of their educational services and workplace culture.